I forgor about this workshop thread for a minute. Here’s what’s up.

Water damaged Kaly 2.0: Owner decided it wasn’t worth it, parted out the board and sold the stormcore back to me  Oh well.

Oh well.

My kaly, which I have since named Dawn, works like a charm. It needs some major cosmetic work, including a nice skinning

also thru hole bolts are ugly. needs some inserts.

The board is so much fun and is so damn comfortable. I’ve given it the nickname wobblemonster as you can’t comfortably go 30 on it. I haven’t gone above 28 on this board, and I’m totally happy with that. Battery also lasts forever (abt 50 miles even with my 200lb fat self) because of the high final drive ratio and the lowish battery current settings (35 per side)

(ignore the top speed, I did a burnout and it fucked it all up. Ride with

@jack.luis last month)

Next on the agenda is my mountainboard. Since the conception of the idea for the kaly, I’ve wanted something that was RKP on a mtb deck. My first attempt last month was with BN270 on a trampa holypro, but unfortunately, the hangers weren’t wide enough for deck clearance with geardrives.

This setup was using 8" aliexpress tires on torqueboards hubs.

Video of me fucking around with this setup after I got my bindings

This was fun, and I liked how narrow the setup was, but geardrives were a must. I’m waiting for the next batch of lunas and moondrives as they’ll be available with a 6.5:1 gear ratio

I knew I wanted to go HV with this build as I was itching to use a ubox so I could run an unreasonably high phase current, and I wanted to stick to higher KV to run the most efficient setup I could with mechanical gear reduction rather than electrical reduction through lower KV. I’ve now settled on this ratio with 190kv motors and 9" tires on mbs fivestars

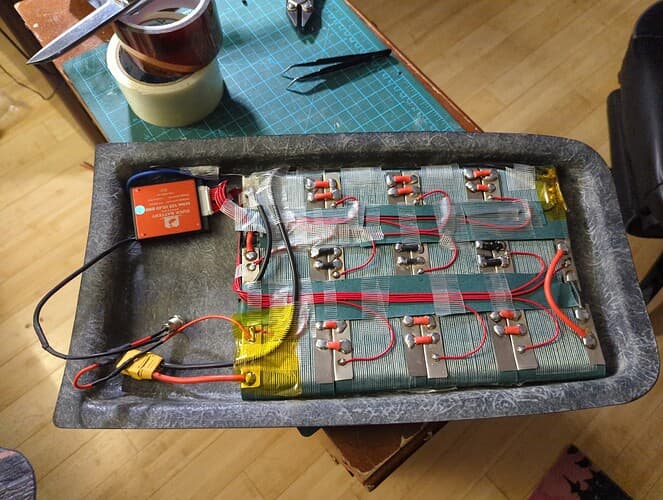

I’m hoping to push 30 miles our of this 48 cell pack. Speaking of 48 cell pack, I’m almost done with it. I did most of the work a month or so back, and left it sitting as I got lazy and didn’t feel like installing my LLT bms yet.

Pack fits in a peli 1150.

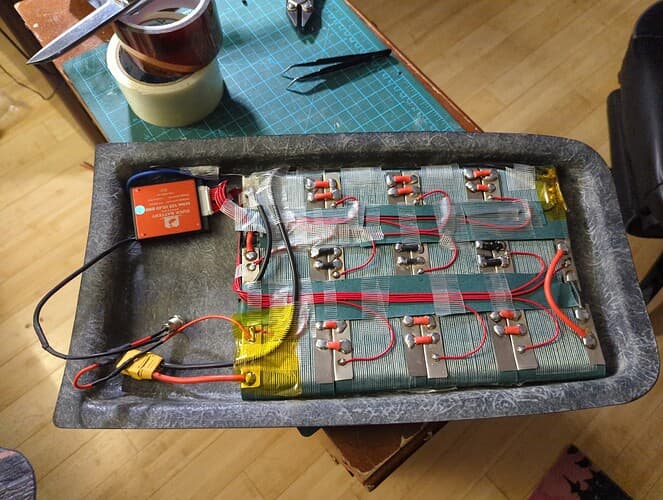

Last thing I have is this 12s3p p42a I built for a loaded omakase. I cant find the final picture where I added some more insulation around that negative discharge and added some more tape to hold everything down, but this is about what it looked like.

Oh well.

Oh well.